Testimonials

Corse Automotive & Motorsport

“Daryl was responsible for the initial design modifications to convert a road vehicle to race specifications. His engineering, fabrication, machining and CAD skills make him extremely versatile.

In addition, his workmanship is excellent and thorough. Daryl is flexible and willing to work on any project assigned to him”.

Mick Mitchell

Director

Corse Automotive & Motorsport

2006

IVR Group

“IVR Group has engaged the services of Daryl Perusic under Perusic Engineering for the past 7 years to assist and lead our development in project engineering and the research, testing and innovation of our product and system offerings.

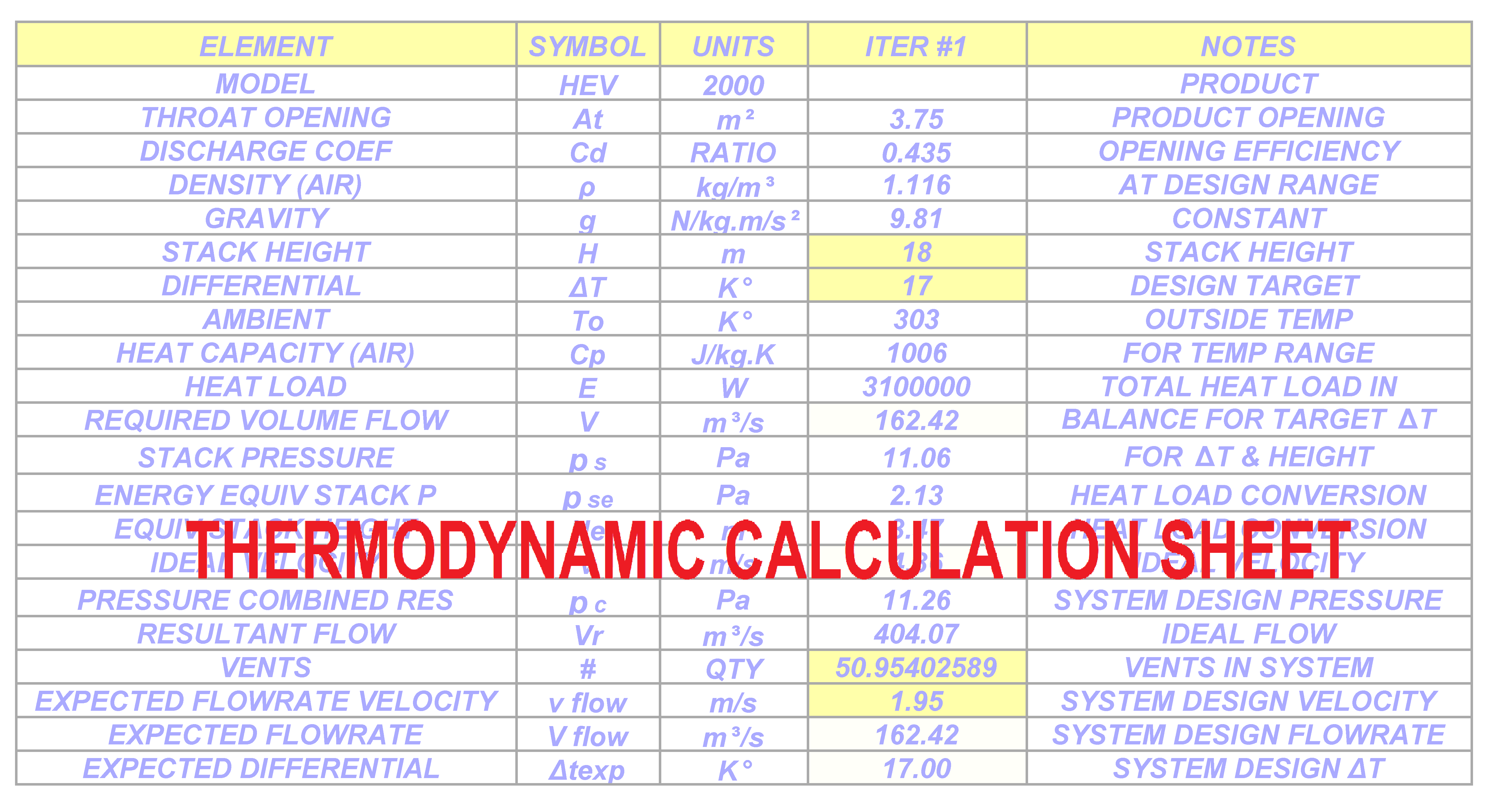

During this time Daryl has been involved in a range of natural ventilation and smoke hazard management projects for the Australian Defence Force, Xstrata, Rio Tinto, BHP Billiton, Sydney Water, Multiplex and Railcorp. His roles and responsibilities during these projects have included thermodynamic and fluid dynamic analysis, structural analysis and production mechanics.

Daryl has also been extensively been involved in product research and development including modelling, physical testing for a range of performance factors related to natural ventilation, and has represented IVR when working with organisations including ARUP, CSIRO and Standards Australia.

With a renowned focus on detail and integrity, passion for sustainable practices, and expertise in air flow performance, Daryl has become a valued contributor to IVR Group as the overseeing engineer for our operations.

IVR Group would like to express our recognition and thanks for the skills, experience, professionalism and passion that Daryl has brought to our organisation and would recommend Daryl Perusic and Perusic Engineering to any firm that is seeking services that he provides”.

Warwick Goodsell

Marketing & Technical Design

IVR Group

2012

Bluescope Port Kembla

“I would like to inform you of the temperatures measured within the MCL after the installation of the roof ventilators and side wall louvres.

Design change in temperature (ΔT) between outside ambient air and inside air was 17°C.

Prior to installation the ΔT was 30 – 35°C.

After installation ΔT was 17°C on the west side and 15°C on the east side of the building.

We have experienced no leaks in the roof and the general consensus at the MCL is the addition of the roof ventilators has made a dramatic improvement to the extreme temperatures previously experienced within the building and around equipment.

I would also like to say that I was particularly impressed with the high quality of fabrication of the components supplies in a very short time frame. Your engineering design and workshop teams should be congratulated.

Thanks again for all your help. It is appreciated”.

Rhys Ovenden

Senior Mechanical Projects Engineer

BlueScope Steel Port Kembla

2013

Editorial SMH

Ross Greenwood

Financial Expert

News Limited

Daily Telegraph, 4th November 2014

Read Article

For a discussion on how we can help you, give us a call on 0415 586 890